Other important information for a proper pump selection is also included like efficiency curves npsh r curve pump curves for several impeller diameters and different speeds and power consumption. The centrifugal pump converts mechanical energy into hydraulic energy flow velocity and pressure and the ac motor converts electrical energy into mechanical energy.

Understanding Pump Curves Pumps Systems

Understanding Pump Curves Pumps Systems

These efficiency curves intersect with the head flow curves and are labeled with percentages.

Water pump efficiency curve. On the pumping plant and water may be wasted. In the case of this pump the best efficiency point bep falls at approximately 1075 gpm at 95 ft and efficiency at bep is 841. The system head capacity curve dictates where a pump will operate on its h q curve the pump will always operate at the intersection between the pump and system h q curves and how far it will operate away from its best efficiency flow rate.

However since no pump is 100 efficient every pump will require more input power than it will generate in water horsepower. A pump manufacturer conducts a variety of tests and the findings are then reflected on a graph which we refer to as the pump curve. Pump efficiency pump efficiency is defined as the ratio of water horsepower output from the pump to the shaft horsepower input for the pump.

A pump performance curve is simply a graph or chart that represents the performance capabilities of a given water pump. The pump performance curve also provides efficiency curves. The efficiency varies throughout the operating range.

The pump performance curve describes the relation between the flowrate and the head for the actual pump. Jordan an application engineer at crane engineering explains how to read a centrifugal pump curve in the video below. In the pump industry much of the work involves two extremely simple yet efficient machinesthe centrifugal pump and the ac induction motor.

Knowing how to read a centrifugal pump curve is essential to the health of your system. Pump curves are essentially data about a given pumps ability to produce flow against certain head. Some curves will also mark the best efficiency point bep.

Water horsepower is determined by the flow rate and pressure delivered from the pump. The purpose of the european guide to pump efficiency for single stage centrifugal pumps was to help purchasers choose pumps of good efficiency. Operation over a pumps range of flow rates as a function the pump best efficiency flow rate.

In our same example with the 79 impeller we can see that at 140 gallons per minute the pump is operating at 72 efficiency. The shaft horsepower is delivered to the. When youre reading a curve the pumps flow rate will be on the top and bottom and its height to push is on the sides.

This guide should only be used for single stage centrifugal pumps handling clean water at up to 95 c. Running too far out on the curve or too far back can cause damage to the pump excessive energy consumption and overall poor performance.

Polymer Solutions To Improve The Efficiency Of Water Systems

Polymer Solutions To Improve The Efficiency Of Water Systems

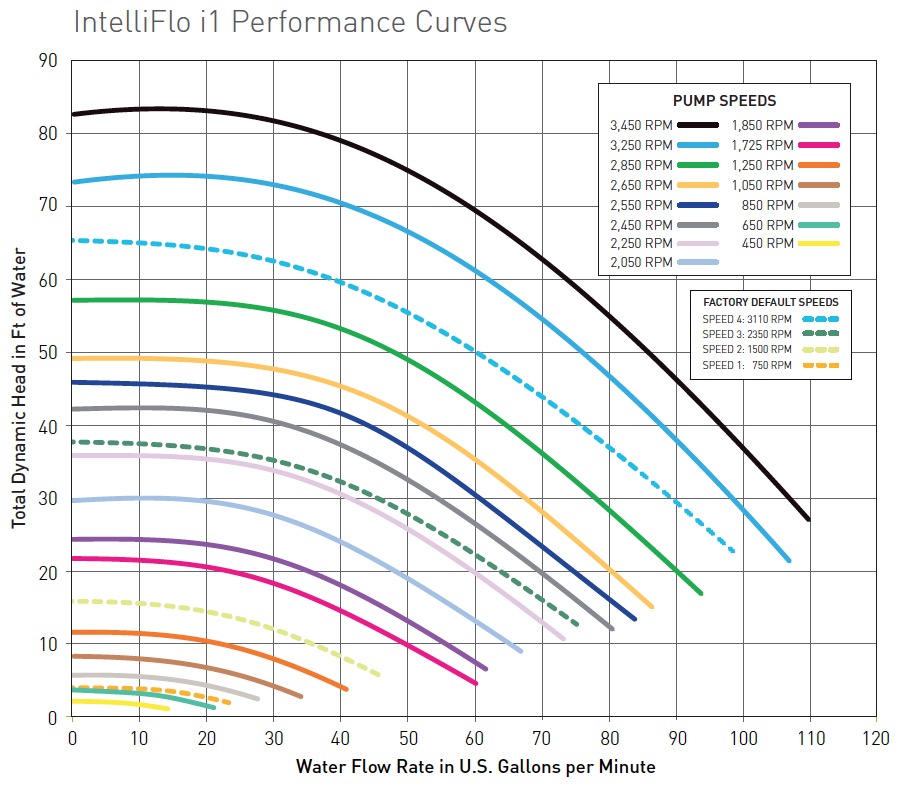

Why Oversize A Variable Speed Pool Pump Florida Solar Design Group

Why Oversize A Variable Speed Pool Pump Florida Solar Design Group

Http Www Nesc Wvu Edu Pdf Dw Publications Ontap Tech Brief Tb55 Pumpcurves Pdf

Whisperflo Pool Pump Pentair Swimming Pool Pumps

Whisperflo Pool Pump Pentair Swimming Pool Pumps

How To Calculate Water System Btu Measurements Contracting Business

How To Calculate Water System Btu Measurements Contracting Business

Pumps Pump Performance Curves Ctg Technical Blog

Pumps Pump Performance Curves Ctg Technical Blog

Pentair Sta Rite Ds3 Series Pro Storm Medium Head Centrifugal

Pentair Sta Rite Ds3 Series Pro Storm Medium Head Centrifugal

![]() Series Or Parallel Pump Operation Mc Nally Institute

Series Or Parallel Pump Operation Mc Nally Institute

Vacuum Pumps For Lithium Batteries Performance Curve Vacuum Pump

Vacuum Pumps For Lithium Batteries Performance Curve Vacuum Pump

Elpumps Com Submersible Deep Well Tube Pumps For Clean Water

Elpumps Com Submersible Deep Well Tube Pumps For Clean Water

Post a Comment

Post a Comment